You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So TASL has been accumulating experience with all those Fuselage manufacturing. Can anyone tell me is it like those archaic HAL doing things or TASL using AFP and Automated Drilling aka latest Industrial Processes to do things?

Since its for a foreign OEM, we can expect mfg is done as per OEM choice/guideline and very likely the production line is also only for the OEM orders ie that line will not be involved/used to mfg or serve other orders. The machinery are also all set up accordingly the OEM choice and from only the OEM approved source/make. The same go for raw material, QAP and fixtures/jigs too.So TASL has been accumulating experience with all those Fuselage manufacturing. Can anyone tell me is it like those archaic HAL doing things or TASL using AFP and Automated Drilling aka latest Industrial Processes to do things?

Pahalgam attack aftermath: Ammunition manufacturing companies cancel long leaves of employees

Pahalgam attack: Twenty-six people, mostly tourists, were killed and several were injured when terrorists opened fire at a meadow near the popular tourist town of Pahalgam in south Kashmir's Anantnag district on April 22.

Pahalgam attack aftermath: Long leaves cancelled at ordnance factories | India News - The Times of India

India News: Following the Pahalgam terror attack and heightened tensions with Pakistan, Munitions India Limited (MIL) has reportedly cancelled extended leaves for

1. Increase in export orders.

2. "The current situation with Pakistan"

The OFB units which have seen leave cancellation are specifically engaged in medium artillery ammo production.

Pahalgam attack aftermath: Ammunition manufacturing companies cancel long leaves of employees

Pahalgam attack: Twenty-six people, mostly tourists, were killed and several were injured when terrorists opened fire at a meadow near the popular tourist town of Pahalgam in south Kashmir's Anantnag district on April 22.www.indiatvnews.com

Some OFB units have cancelled leaves to increase production of ammunition and weapons citing the reasons:

Pahalgam attack aftermath: Long leaves cancelled at ordnance factories | India News - The Times of India

India News: Following the Pahalgam terror attack and heightened tensions with Pakistan, Munitions India Limited (MIL) has reportedly cancelled extended leaves fortimesofindia.indiatimes.com

1. Increase in export orders.

2. "The current situation with Pakistan"

RFMW proudly participated in SMART 2025 as a Gold Sponsor, hosted by LRDE-DRDO in Bengaluru. We showcased innovations in RF & Radar, including OMNIVIS (77GHz), RFSoC (6–18GHz), AESA tech, high-power SSPA & miniaturized frontends.

Per the BEL concall , Govt has asked all msmes and vendors to ramp up supplies and expedite the current defence orders in a need of the hour manner. This is likely the message given in the meeting with the companies reps. Interesting times ahead.

BEL also working with DRDO for new orders

BEL also working with DRDO for new orders

Defence Research and Development Organisation (DRDO) Chairman Dr Samir V Kamat, accompanied by Solar Industries India Ltd Chairman Satyanarayan Nuwal, reviews the manufacturing processes of various defence products at Solar Industries India Ltd headquarters in Nagpur, Maharashtra.

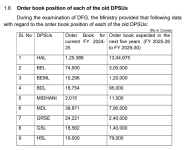

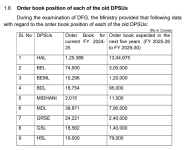

Was going thru the Sansad docs earlier. While the estimates are always forward looking and hardly real indicator due to delays in ordering, but HAL estimate for next 5 fiscals seem way too big considering some big tickets are already placed in 24-25 FY ? Unless a decent LSP amca or substantial mk2 nos happen, 13 lakh crores over 5 years is huge. Maybe those 414 engines are going to cost a fortune ?

Heli orders, ROH, extra engines, super su30 , uttam prod all would be ~ 4-5 lakh crores at best, leaves out huge amount. Indicative of unit prices of the new jets will be very high.

Heli orders, ROH, extra engines, super su30 , uttam prod all would be ~ 4-5 lakh crores at best, leaves out huge amount. Indicative of unit prices of the new jets will be very high.

Karnataka wins Tata- Airbus helicopter manufacturing unit

Airbus and Tata Advanced Systems will establish an H125 helicopter final assembly line in Kolar, Karnataka, marking India's first private helicopter assembly facility.European aviation major Airbus and Tata Advanced Systems (TASL), the aerospace arm of the Tata group, will set up the Final Assembly Line (FAL) for the H125 helicopters for the Indian Air Force (IAF) in Kolar, Karnataka, people aware of the development said.

The facility is India’s first privately-led helicopter assembly facility and is a shot in the arm of the government’s Make in India campaign as part of which the government is trying to build self-reliance in aerospace manufacturing.

The factory will produce Airbus’ best-selling H125 helicopter from its civil range for India and the neighbouring countries and will be the fourth such facility in the world after France, US and Brazil. It will start with a production capacity of 10 helicopters per year but will see expansion as Airbus has projected a demand for 500 light helicopters of the H125 class in the country and south Asia in the next 20 years.

The people quoted above said that the plant will be set up in the Vemgal Industrial area which is around two hours from Bengaluru and already houses other facilities of TASL including a satellite manufacturing plant.

Spokespersons of Airbus and TASL didn’t reply to queries. Gunjan Krishna, commissioner for industrial development and director, industries department of Karnataka refused to speak on the topic as the discussions were confidential.

Karnataka, they said, was chosen among multiple other locations in Andhra Pradesh, Uttar Pradesh and Gujarat due to the state’s established ecosystem in aerospace manufacturing.

While Anantapur in Andhra Pradesh which gained international recognition after becoming home to Kia Motors’ manufacturing unit was a strong contender, Karnataka was chosen due to its strong ancillary support ecosystem besides being a hub for TASL which will build the plant.

The Tata-owned company recently acquired 7.4 lakh sq. ft. plot in Karnataka’s Vemgal Industrial Area for the establishment of an aircraft manufacturing and final assembly line, including Maintenance, Repair, and Overhaul (MRO) facilities.

“The locations were apprised based on their logistics facility, expansion potential, availability of skilled workforce and promises of the state government like fast track approval of permissions,” a person involved in the project said.

He said that Vemgal has potential of expansion including setting up of helipads which is a must for a final assembly line for testing of aircraft before delivery.

Besides that the state as part of its aerospace and defence policy has also promised subsidy on land including capital investment, stamp duty, incentives in electricity charges and production linked incentives of 1% of annual turnover for a period of 5 years.

“This will not only strengthen indigenous manufacturing capabilities but also act as a catalyst for developing advanced industrial clusters," said Aravind Melligeri, executive chairman & CEO, Aequs a major aerospace manufacturer which counts Airbus as a customer.

Initiatives like this drive skill development, attract supply chain investments, and create high-value employment, accelerating the transformation of India into a globally competitive and strategic node in global aerospace manufacturing,”

Tata and Airbus are also setting up a final assembly line for the C295 aircraft in Vadodara, Gujarat. Gujarat has recently bagged multiple high-ticket investment projects including multiple semiconductor plants, C295 aircraft and the international diamond bourse leading to accusations from opposition political leaders that the state was being favoured by the central government.

should hire South Africans, Italians etc as consultants.BEL hiring advisors for weapon systems projects. They are definitely in for several projects dcpp most likely those BDL won't be doing. Certainly won't restrict to Israeli and French products alone. Below is one example, there are more.

View attachment 43778