You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Naval Aviation Indigenisation Roadmap (2019-22)

https://www.indiannavy.nic.in/sites/default/files/Naval Indigenisation Road Map 2019-22.pdf

The two Naval Aircraft Yards (NAYs) at Kochi and Goa,along with the Naval Aircraft Servicing and DevelopmentOrganisation (NASDO) at Goa, continue to spearhead aviation’s indigenisation efforts. NAY (Goa) is responsiblefor Russian-origin spares, NAY (Kochi) for western-originspares and NASDO focuses on common equipment. Theseorganisations are known as the ‘In-house IndigenisationCommittees (IICs)’.The industry may identify the items they can indigenise and directly approach the respective IIC to initiate theprocess. The projects can then be pursued under Revenueprocurement route or through ‘Make-II‘ of the Defence Procurement Procedure (DPP) or other appropriate channels,according to Indian Navy officials.The NAIR is expected to drive the government’s ‘Make inIndia‘ initiative and the concerted efforts of the stakeholderswould ensure indigenous availability of required equipmentand self-reliance.

https://www.indiannavy.nic.in/sites/default/files/Naval Indigenisation Road Map 2019-22.pdf

The two Naval Aircraft Yards (NAYs) at Kochi and Goa,along with the Naval Aircraft Servicing and DevelopmentOrganisation (NASDO) at Goa, continue to spearhead aviation’s indigenisation efforts. NAY (Goa) is responsiblefor Russian-origin spares, NAY (Kochi) for western-originspares and NASDO focuses on common equipment. Theseorganisations are known as the ‘In-house IndigenisationCommittees (IICs)’.The industry may identify the items they can indigenise and directly approach the respective IIC to initiate theprocess. The projects can then be pursued under Revenueprocurement route or through ‘Make-II‘ of the Defence Procurement Procedure (DPP) or other appropriate channels,according to Indian Navy officials.The NAIR is expected to drive the government’s ‘Make inIndia‘ initiative and the concerted efforts of the stakeholderswould ensure indigenous availability of required equipmentand self-reliance.

The NAIR is expected to drive the government’s ‘Make in India‘ initiative and the concerted efforts of the stakeholders would ensure indigenous availability of required equipmentand self-reliance.

@nair

Cochin Shipyard mulls cautious expansion, to grow ship repair business

Nair said India should do much more of ship repair, given the country's location and good-quality manpower.

By Aditi Divekar | Mumbai

Last Updated at January 29, 2020 15:02 IST

Amid the not-so-good business climate for ship building, state-owned Cochin Shipyard has prepared a cautiously sizable growth plan.

Expansion of the repair business, foray into the volume-based business of fishing boats, and eyeing Indian Navy projects and the private tourism sector are some.

“We are looking to up our ship repair turnover and have moved into profit sharing agreements with both Mumbai and Kolkata port trusts. We see an additional revenue of Rs 70-80 crore from Mumbai alone in FY20 itself. In the next two years, our revenue from the Mumbai port alone should be above Rs 200 crore,” Madhu Nair, chairman and managing director, told Business Standard.

Currently, about 70 per cent of the revenue comes from the ship building business and the rest from ship repair. “We are also investing Rs 80 crore at the Mumbai port for a floating dry dock and Rs 20 crore at the Kolkata port,” said Nair. An agreement is in place between each of the ports and Cochin Shipyard, creating an asset-light model for the latter.

Nair said India should do much more of ship repair, given the country’s location and good-quality manpower.

Cochin Shipyard was also in talks with the Mormugao Port Trust for their ship repair facility but could not take this ahead, due to vessel size limitations. “Between our own repair facility, along with the Mumbai and Kolkata ports, we can now handle large and mid-sized ship repairs. We were, therefore, on a lookout for a small-sized ship repair facility. Goa should have been small but it did not fit,” said Nair.

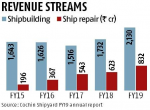

Though revenue consistently rose between 2014-15 and 2018-19, growth in the ship building business income was not as impressive as in the repair section.

According to the latest annual report, the yard built 20 defence vessels, 15 large vessels, 35 offshore support vessels and 52 small and medium vessels. These figures are unchanged from the preceding year.

The company has taken 42 acres on lease at the Cochin shipyard where it aims to shift the repair facility for smaller and mid-size vessels. The facility is expected to add revenue by 15-20 per cent in the next two years. The target is to handle 80 ships a year. It also is not affected from the current order flow vagary due to the new IMO 2020 sulphur cap regulations.

These affect merchant vessels, a space where Cochin Shipyard is not present. “We have a slightly different product mix — it is largely naval ships, which do not use heavy fuel oil,” says Nair. No Indian shipyard is in the affected segment — L&T’s in Tamil Nadu, Hindustan Shipyard at

Visakhapatnam and Reliance Naval and Engineering Company, for instance.

Apart from the repair business, the company is looking at the building of fishing boats. “In this business, we will play on the volume game. One of these ships costs (only) Rs 1-1.5 crore but the volume is over 100 or more vessels (yearly) in terms of order flow,” said Nair.

It is for the same reason that the company is eyeing insolvent Temba Shipyard, subsidiary of Bharti Shipyard, which has yards in Malpe, Karnataka, and in Tamil Nadu. “We see value in Temba as it is located in an area which is a fishing boat hub and can have about 4,000 boats,” said Nair. All projects put together, Cochin Shipyard has an investment plan of Rs 3,500 crore. The majority of this money is to come from internal accrual.

With an eye on growing the ship repair business segment at Port Blair, the company is to look at operations and management of the repair facility at Netaji Subhas Dock, Kolkata. It expects this to aid its working with the navy in the Andaman region and with private tourism.

Cochin Shipyard mulls cautious expansion, to grow ship repair business

Nair said India should do much more of ship repair, given the country's location and good-quality manpower.

By Aditi Divekar | Mumbai

Last Updated at January 29, 2020 15:02 IST

Amid the not-so-good business climate for ship building, state-owned Cochin Shipyard has prepared a cautiously sizable growth plan.

Expansion of the repair business, foray into the volume-based business of fishing boats, and eyeing Indian Navy projects and the private tourism sector are some.

“We are looking to up our ship repair turnover and have moved into profit sharing agreements with both Mumbai and Kolkata port trusts. We see an additional revenue of Rs 70-80 crore from Mumbai alone in FY20 itself. In the next two years, our revenue from the Mumbai port alone should be above Rs 200 crore,” Madhu Nair, chairman and managing director, told Business Standard.

Currently, about 70 per cent of the revenue comes from the ship building business and the rest from ship repair. “We are also investing Rs 80 crore at the Mumbai port for a floating dry dock and Rs 20 crore at the Kolkata port,” said Nair. An agreement is in place between each of the ports and Cochin Shipyard, creating an asset-light model for the latter.

Nair said India should do much more of ship repair, given the country’s location and good-quality manpower.

Cochin Shipyard was also in talks with the Mormugao Port Trust for their ship repair facility but could not take this ahead, due to vessel size limitations. “Between our own repair facility, along with the Mumbai and Kolkata ports, we can now handle large and mid-sized ship repairs. We were, therefore, on a lookout for a small-sized ship repair facility. Goa should have been small but it did not fit,” said Nair.

Though revenue consistently rose between 2014-15 and 2018-19, growth in the ship building business income was not as impressive as in the repair section.

According to the latest annual report, the yard built 20 defence vessels, 15 large vessels, 35 offshore support vessels and 52 small and medium vessels. These figures are unchanged from the preceding year.

The company has taken 42 acres on lease at the Cochin shipyard where it aims to shift the repair facility for smaller and mid-size vessels. The facility is expected to add revenue by 15-20 per cent in the next two years. The target is to handle 80 ships a year. It also is not affected from the current order flow vagary due to the new IMO 2020 sulphur cap regulations.

These affect merchant vessels, a space where Cochin Shipyard is not present. “We have a slightly different product mix — it is largely naval ships, which do not use heavy fuel oil,” says Nair. No Indian shipyard is in the affected segment — L&T’s in Tamil Nadu, Hindustan Shipyard at

Visakhapatnam and Reliance Naval and Engineering Company, for instance.

Apart from the repair business, the company is looking at the building of fishing boats. “In this business, we will play on the volume game. One of these ships costs (only) Rs 1-1.5 crore but the volume is over 100 or more vessels (yearly) in terms of order flow,” said Nair.

It is for the same reason that the company is eyeing insolvent Temba Shipyard, subsidiary of Bharti Shipyard, which has yards in Malpe, Karnataka, and in Tamil Nadu. “We see value in Temba as it is located in an area which is a fishing boat hub and can have about 4,000 boats,” said Nair. All projects put together, Cochin Shipyard has an investment plan of Rs 3,500 crore. The majority of this money is to come from internal accrual.

With an eye on growing the ship repair business segment at Port Blair, the company is to look at operations and management of the repair facility at Netaji Subhas Dock, Kolkata. It expects this to aid its working with the navy in the Andaman region and with private tourism.

Cochin Shipyard mulls cautious expansion, to grow ship repair business

HAL to make advanced armed UAVs with Israeli Co

In a first, advanced Unmanned Combat Aerial Vehicles (UCAVs) will be manufactured in India, with leading aeronautical entity Hindustan Aeronautics LtdNSE 1.42 % (HAL) set to formalise a partnership with an Israeli firm that specializes in autonomous weaponry.

The advanced Heron TP, which belongs to the Medium Altitude Long Endurance (MALE) class with an endurance of over 36 hours, will be manufactured to cater both to Indian requirements for a combat UAV and possibly exports to third nations in the future as well.

HAL is set to sign a partnership pact with Israel Aerospace Industries (IAI) at the upcoming DefExpo 2020 in Lucknow this week, with estimates that in the Indian market alone, there is a requirement of at least 100 drones of this type. The Heron TP is an advanced version of the Heron UAVs that are currently in service with the three forces in a reconnaissance role.

HAL, which is India’s leading aeronautical company, is looking ahead to commence full production of the armed drones, its chairman and managing director R Madhavan confirmed to ET.

Details of the weaponry onboard are still not clear as the choice of payload is usually left to the user, which in this case would be the three armed forces. Given the flexibility displayed by Israel in joint collaborations in the past, Indian air-to-ground weapons could be integrated with the Heron TPs.

Once finalized, this would be the second range of Israeli UAVs to be made in India, with a joint plant by an Adani-Elbit combine also producing the unarmed Hermes 900 class of drones for export orders from Hyderabad.

The HAL chairman also told ET that the company is actively working on another project for a 200 kg class rotor wing UAV, which among other tasks, will be useful for dropping supplies to troops posted at high altitude areas like the Siachen glacier.

The under development UAV—work on sensors, payloads and other data links has been outsourced to institutions like the Indian Institute of Technology—is being designed specially to carry a 40 kg payload to high altitude areas.

This would drastically cut down supply time for vital loads like medicine and food that are currently transported by mules and are prone to high risk, given severe weather and the dangers of avalanches that have claimed numerous lives. Israel Aerospace Industries, which says that it has conducted business deals in India that totalled close to $ 5 billion in the past five years, will be showcasing its capabilities at the DefExpo in Lucknow.

In the past, IAI has sold multiple air defence systems to India, as well as the range of Heron UAVs.

HAL to make advanced armed UAVs with Israeli Co

In a first, advanced Unmanned Combat Aerial Vehicles (UCAVs) will be manufactured in India, with leading aeronautical entity Hindustan Aeronautics LtdNSE 1.42 % (HAL) set to formalise a partnership with an Israeli firm that specializes in autonomous weaponry.

The advanced Heron TP, which belongs to the Medium Altitude Long Endurance (MALE) class with an endurance of over 36 hours, will be manufactured to cater both to Indian requirements for a combat UAV and possibly exports to third nations in the future as well.

HAL is set to sign a partnership pact with Israel Aerospace Industries (IAI) at the upcoming DefExpo 2020 in Lucknow this week, with estimates that in the Indian market alone, there is a requirement of at least 100 drones of this type. The Heron TP is an advanced version of the Heron UAVs that are currently in service with the three forces in a reconnaissance role.

HAL, which is India’s leading aeronautical company, is looking ahead to commence full production of the armed drones, its chairman and managing director R Madhavan confirmed to ET.

Details of the weaponry onboard are still not clear as the choice of payload is usually left to the user, which in this case would be the three armed forces. Given the flexibility displayed by Israel in joint collaborations in the past, Indian air-to-ground weapons could be integrated with the Heron TPs.

Once finalized, this would be the second range of Israeli UAVs to be made in India, with a joint plant by an Adani-Elbit combine also producing the unarmed Hermes 900 class of drones for export orders from Hyderabad.

The HAL chairman also told ET that the company is actively working on another project for a 200 kg class rotor wing UAV, which among other tasks, will be useful for dropping supplies to troops posted at high altitude areas like the Siachen glacier.

The under development UAV—work on sensors, payloads and other data links has been outsourced to institutions like the Indian Institute of Technology—is being designed specially to carry a 40 kg payload to high altitude areas.

This would drastically cut down supply time for vital loads like medicine and food that are currently transported by mules and are prone to high risk, given severe weather and the dangers of avalanches that have claimed numerous lives. Israel Aerospace Industries, which says that it has conducted business deals in India that totalled close to $ 5 billion in the past five years, will be showcasing its capabilities at the DefExpo in Lucknow.

In the past, IAI has sold multiple air defence systems to India, as well as the range of Heron UAVs.

HAL to make advanced armed UAVs with Israeli Co

L&T-MBDA missile systems JV units to start deliveries from 2020

By Rachita Prasad

Last Updated: Feb 03, 2020, 04.03 PM IST

The unit includes assembly, inert integration (without explosives) and testing facility for missile sub-systems and missile weapon launch systems spread across an area of 16,000 square meter in a Special Economic Zone at Coimbatore. It is a part of the Tamil Nadu Defence Industrial Corridor. The joint venture was formed in 2017 and it has already received a few export orders.

LTMMSL will build complete missile systems for the Indian Armed Forces, exploring prospects under the various categories for defence procurement.

MUMBAI: Larsen & Toubro’s joint venture with European missile maker MBDA, namely L&T MBDA Missile Systems has set up a missile integration facility in Tamil Nadu to deliver complete missile systems for export markets from 2020, the Indian engineering major said Monday.

The inert integration unit, which excludes explosives, will sell locally and export as well.

JD Patil, chairman L&T MBDA Missile Systems, said, “L&T MBDA Missile Systems has been working proactively to offer advanced missiles and missile systems to the Indian Armed Forces through domestic production. The creation of this new integration facility at Coimbatore is a first step in this direction.”

The unit includes assembly, inert integration (without explosives) and testing facility for missile sub-systems and missile weapon launch systems spread across an area of 16,000 square meter in a Special Economic Zone at Coimbatore. It is a part of the Tamil Nadu Defence Industrial Corridor.

The joint venture was formed in 2017 and it has already received a few export orders, the delivery for which will start in 2020.

Pasquale Di Bartolomeo, vice chairman and member of the board L&T MBDA Missile Systems, said, “With the technical and human capabilities offered by this site, India will be ideally placed to offer its armed forces and the export market the very latest generation of defence equipment technology.”

LTMMSL will build complete missile systems for the Indian Armed Forces, exploring prospects under the various categories for defence procurement. LTMMSL will also address Indian Navy’s air defence requirement for short range surface-to-air missile system.

L&T owns 51% stake in LTMMSL and MBDA owns 49% in the company.

L&T-MBDA missile systems JV units to start deliveries from 2020

By Rachita Prasad

Last Updated: Feb 03, 2020, 04.03 PM IST

The unit includes assembly, inert integration (without explosives) and testing facility for missile sub-systems and missile weapon launch systems spread across an area of 16,000 square meter in a Special Economic Zone at Coimbatore. It is a part of the Tamil Nadu Defence Industrial Corridor. The joint venture was formed in 2017 and it has already received a few export orders.

LTMMSL will build complete missile systems for the Indian Armed Forces, exploring prospects under the various categories for defence procurement.

MUMBAI: Larsen & Toubro’s joint venture with European missile maker MBDA, namely L&T MBDA Missile Systems has set up a missile integration facility in Tamil Nadu to deliver complete missile systems for export markets from 2020, the Indian engineering major said Monday.

The inert integration unit, which excludes explosives, will sell locally and export as well.

JD Patil, chairman L&T MBDA Missile Systems, said, “L&T MBDA Missile Systems has been working proactively to offer advanced missiles and missile systems to the Indian Armed Forces through domestic production. The creation of this new integration facility at Coimbatore is a first step in this direction.”

The unit includes assembly, inert integration (without explosives) and testing facility for missile sub-systems and missile weapon launch systems spread across an area of 16,000 square meter in a Special Economic Zone at Coimbatore. It is a part of the Tamil Nadu Defence Industrial Corridor.

The joint venture was formed in 2017 and it has already received a few export orders, the delivery for which will start in 2020.

Pasquale Di Bartolomeo, vice chairman and member of the board L&T MBDA Missile Systems, said, “With the technical and human capabilities offered by this site, India will be ideally placed to offer its armed forces and the export market the very latest generation of defence equipment technology.”

LTMMSL will build complete missile systems for the Indian Armed Forces, exploring prospects under the various categories for defence procurement. LTMMSL will also address Indian Navy’s air defence requirement for short range surface-to-air missile system.

L&T owns 51% stake in LTMMSL and MBDA owns 49% in the company.

L&T-MBDA missile systems JV units to start deliveries from 2020

India’s Garden Reach Shipbuilders & Engineers Ties Up With Portugal’s BERD For Building Next Generation Modular Bridges Solutions

10 February, 2020

by Manish Kumar Jha

India’s Garden Reach Shipbuilders & Engineers (GRSE) has inked a MoU With Portugal’s BERD for building next generation modular Bridges solutions in India. GRSE, one of the largest DPSUs of India which makes complex naval vessels for the Indian Navy has tied up with world's leading engineering entity, BERD for the Methods and Solutions for Bridge Construction.

On the 3rd Day of DefExpo-2020, a flagship biennial event of the Ministry of Defence, India’s Garden Reach Shipbuilders & Engineers Ltd. (GRSE) and BERD, S.A. (BERD), a Portuguese company, signed a Memorandum of Understanding (MoU), in a ceremony presided by the Defence Minister Rajnath Singh at DEFEXPO 2020 in Lucknow, India.

This MoU relates to the Cooperation between the two companies in the field of Modular Bridges for Military and Civil use. Both Companies aim at expanding their business not only in India but also globally, with a special emphasis on Sri Lanka, Bangladesh, Nepal, Bhutan, and Myanmar among others, by means of offering innovative and technologically advanced solutions.

GRSE derives a significant share of its revenues from its shipbuilding division with warship building capabilities, being also engaged in engine production and other engineering activities. The engineering division manufactures Deck Machinery items, Prefabricated Portable Steel Bridges and Marine Pumps.

Speaking with BW Businessworld, GRSE’s Chairman & Managing Director, RAdm Vipin Kumar Saxena elaborated on the partnership with BERD remarked: “As you know that GRSE is also in the Bailey Bridge manufacturing, which we supply to Indian Army, BRO, State Governments and also export to neighboring countries - Nepal, Bhutan, and Myanmar among others. BERD has got an advance design team for manufacturing light weight, long length and long-life kind of bridges. We will be working out a suitable collaboration with them and in coming year, we will develop new type of Portable Steel Bridges.”

Talking about the collaboration, BERD’s Vice-President, Diogo Graça Moura expressed great expectation about this partnership with GRSE. Building on such next generation technological collaboration in the Modular Bridges, he remarked: "Our partnership with GRSE will unlock new dimensions in the area of Modular Bridges with our cutting edge design team with global expertise and solutions that we strive to bring to India and give a push to ‘Make in India’ Initiative of Govt. of India."

BERD is among the top 3 leaders in the Methods and Solutions for Bridge Construction based on the unique Organic Prestressing System(OPS) that stiffens the machines to build bridges. Born in 2006, as a spin-off of the Faculty of Engineering of Porto University, BERD has participated in the construction of several bridges worldwide.

In the world of complex warships, in 2017, GRSE has built and delivered warships INS Kiltan, an Anti-Submarine Warfare Corvette with superstructure made entirely of composite material. on the future delivery of warships, GRSE is gearing up to deliver a mega project- Stealth Missile Frigate Rear Admiral V K Saxena on the sidelines of Def Expo 2020, told to BW Businessworld that in terms of value, it is Rs 19256 crore and is a very advanced, modern warfare ship from Indian Navy. "It has got very advanced weapon sensors, electronic equipment and stealth features. It is going to be the best and most complex project which we have handled so far in GRSE. It is supposed to be delivered by 2023", he said.

Indian Defence entities have been looking at the international market based on the inherent strength and expertise. According to the ministry of Defence, in 2014, India's defence export was under Rs 2000 crore which has crossed Rs 11000 crore last year. Such international collaborations is also expected to address the capability gaps. In the 'make in India' endeavor, BERD's Diogo Moura pointed out that the there is great expectation out of such cooperation as GRSE is the market leader recognized for its quality and manufacturing capacity and BERD is known as the high quality engineering company spread worldwide.

India’s Garden Reach Shipbuilders & Engineers Ties Up With Portugal’s BERD For Building Next Generation Modular Bridges Solutions

10 February, 2020

by Manish Kumar Jha

India’s Garden Reach Shipbuilders & Engineers (GRSE) has inked a MoU With Portugal’s BERD for building next generation modular Bridges solutions in India. GRSE, one of the largest DPSUs of India which makes complex naval vessels for the Indian Navy has tied up with world's leading engineering entity, BERD for the Methods and Solutions for Bridge Construction.

On the 3rd Day of DefExpo-2020, a flagship biennial event of the Ministry of Defence, India’s Garden Reach Shipbuilders & Engineers Ltd. (GRSE) and BERD, S.A. (BERD), a Portuguese company, signed a Memorandum of Understanding (MoU), in a ceremony presided by the Defence Minister Rajnath Singh at DEFEXPO 2020 in Lucknow, India.

This MoU relates to the Cooperation between the two companies in the field of Modular Bridges for Military and Civil use. Both Companies aim at expanding their business not only in India but also globally, with a special emphasis on Sri Lanka, Bangladesh, Nepal, Bhutan, and Myanmar among others, by means of offering innovative and technologically advanced solutions.

GRSE derives a significant share of its revenues from its shipbuilding division with warship building capabilities, being also engaged in engine production and other engineering activities. The engineering division manufactures Deck Machinery items, Prefabricated Portable Steel Bridges and Marine Pumps.

Speaking with BW Businessworld, GRSE’s Chairman & Managing Director, RAdm Vipin Kumar Saxena elaborated on the partnership with BERD remarked: “As you know that GRSE is also in the Bailey Bridge manufacturing, which we supply to Indian Army, BRO, State Governments and also export to neighboring countries - Nepal, Bhutan, and Myanmar among others. BERD has got an advance design team for manufacturing light weight, long length and long-life kind of bridges. We will be working out a suitable collaboration with them and in coming year, we will develop new type of Portable Steel Bridges.”

Talking about the collaboration, BERD’s Vice-President, Diogo Graça Moura expressed great expectation about this partnership with GRSE. Building on such next generation technological collaboration in the Modular Bridges, he remarked: "Our partnership with GRSE will unlock new dimensions in the area of Modular Bridges with our cutting edge design team with global expertise and solutions that we strive to bring to India and give a push to ‘Make in India’ Initiative of Govt. of India."

BERD is among the top 3 leaders in the Methods and Solutions for Bridge Construction based on the unique Organic Prestressing System(OPS) that stiffens the machines to build bridges. Born in 2006, as a spin-off of the Faculty of Engineering of Porto University, BERD has participated in the construction of several bridges worldwide.

In the world of complex warships, in 2017, GRSE has built and delivered warships INS Kiltan, an Anti-Submarine Warfare Corvette with superstructure made entirely of composite material. on the future delivery of warships, GRSE is gearing up to deliver a mega project- Stealth Missile Frigate Rear Admiral V K Saxena on the sidelines of Def Expo 2020, told to BW Businessworld that in terms of value, it is Rs 19256 crore and is a very advanced, modern warfare ship from Indian Navy. "It has got very advanced weapon sensors, electronic equipment and stealth features. It is going to be the best and most complex project which we have handled so far in GRSE. It is supposed to be delivered by 2023", he said.

Indian Defence entities have been looking at the international market based on the inherent strength and expertise. According to the ministry of Defence, in 2014, India's defence export was under Rs 2000 crore which has crossed Rs 11000 crore last year. Such international collaborations is also expected to address the capability gaps. In the 'make in India' endeavor, BERD's Diogo Moura pointed out that the there is great expectation out of such cooperation as GRSE is the market leader recognized for its quality and manufacturing capacity and BERD is known as the high quality engineering company spread worldwide.

India’s Garden Reach Shipbuilders & Engineers Ties Up With Portugal’s BERD For Building Next Generation Modular Bridges Solutions

Chennai based start-up uses diamond to help hypersonic missile re-entry

Published: 11th February 2020 06:22 AM

A Chennai based tech start-up has developed a technology that can be used in Indian hyper-sonic missiles during their re-entry into Earth’s atmosphere.

CHENNAI: A Chennai based tech start-up has developed a technology that can be used in Indian hypersonic missiles during their re-entry into Earth’s atmosphere. Hypersonic missiles, which travel at speeds greater than the speed of sound waves, face destructively high temperatures (>2,400oC) during their re-entry into earth’s atmosphere.

Kapindra Precision Engineering, a tech start-up incubated by Indian Institute of Technology, Madras (IIT-M), developed diamond coatings that can aid effective heat dissipation in such scenarios, said a statement issued by IIT-M on Monday.

The technology proposed in this involves growing a protective layer (few microns thick) consisting of thin films of diamond. It is interesting to note that even though diamond is electrically insulating, its thermal conductivity (2000 W/m-K) is 5 times that of copper. So, diamond coatings act as heat-spreaders in electronic devices and find applications in space technology.

Defence establishments of many countries have been working on heat dissipation issues, which pose a major hurdle to aerodynamic stability of missiles upon re-entry. Usually, improper and inadequate dissipation of heat, during re-entry of missiles, leads to its intense wear and tear.

Based on their technology, Kapindra was adjudged as the ‘#1 Start-up’ in the ‘DRDO Dare to Dream Innovation Contest’ for its specialised product offering.

The start-up came from technology developed at IIT Madras’ Nano Functional Materials Technology Centre (NFMTC) and Materials Science Research Center (MSRC), led by Prof MS Ramachandra Rao, Department of Physics, IIT Madras.

‘Diamond an ultimate material for space tech’

Rao termed diamond as an ultimate engineering material with a plethora of application prospects and states that it is the material to explore for 'quantum computing' with the creation of 'N-V centres in diamond' - a very challenging and futuristic area of research.

Kapindra Precision Engineering works on development and application of specialized coatings for components used in strategic products that demand reduction of friction, wear and tear, and promote heat dissipation.

Kapindra's unique diamond coating technology through its special patented microstructure, offers better surface adhesion on the substrate-side while providing lesser friction and wear on the functional-side on various types of substrate materials and shapes.

Heat dissipation made effective

The usage of diamond is substantiated by its thermal conduction property, which is 5 times that of copper. Diamond coatings can act as heat spreaders in electronic devices and in space technology applications.

Chennai based start-up uses diamond to help hypersonic missile re-entry

Published: 11th February 2020 06:22 AM

A Chennai based tech start-up has developed a technology that can be used in Indian hyper-sonic missiles during their re-entry into Earth’s atmosphere.

CHENNAI: A Chennai based tech start-up has developed a technology that can be used in Indian hypersonic missiles during their re-entry into Earth’s atmosphere. Hypersonic missiles, which travel at speeds greater than the speed of sound waves, face destructively high temperatures (>2,400oC) during their re-entry into earth’s atmosphere.

Kapindra Precision Engineering, a tech start-up incubated by Indian Institute of Technology, Madras (IIT-M), developed diamond coatings that can aid effective heat dissipation in such scenarios, said a statement issued by IIT-M on Monday.

The technology proposed in this involves growing a protective layer (few microns thick) consisting of thin films of diamond. It is interesting to note that even though diamond is electrically insulating, its thermal conductivity (2000 W/m-K) is 5 times that of copper. So, diamond coatings act as heat-spreaders in electronic devices and find applications in space technology.

Defence establishments of many countries have been working on heat dissipation issues, which pose a major hurdle to aerodynamic stability of missiles upon re-entry. Usually, improper and inadequate dissipation of heat, during re-entry of missiles, leads to its intense wear and tear.

Based on their technology, Kapindra was adjudged as the ‘#1 Start-up’ in the ‘DRDO Dare to Dream Innovation Contest’ for its specialised product offering.

The start-up came from technology developed at IIT Madras’ Nano Functional Materials Technology Centre (NFMTC) and Materials Science Research Center (MSRC), led by Prof MS Ramachandra Rao, Department of Physics, IIT Madras.

‘Diamond an ultimate material for space tech’

Rao termed diamond as an ultimate engineering material with a plethora of application prospects and states that it is the material to explore for 'quantum computing' with the creation of 'N-V centres in diamond' - a very challenging and futuristic area of research.

Kapindra Precision Engineering works on development and application of specialized coatings for components used in strategic products that demand reduction of friction, wear and tear, and promote heat dissipation.

Kapindra's unique diamond coating technology through its special patented microstructure, offers better surface adhesion on the substrate-side while providing lesser friction and wear on the functional-side on various types of substrate materials and shapes.

Heat dissipation made effective

The usage of diamond is substantiated by its thermal conduction property, which is 5 times that of copper. Diamond coatings can act as heat spreaders in electronic devices and in space technology applications.

Chennai based start-up uses diamond to help hypersonic missile re-entry

I doubt its a new design. I mean its the OFB. Designing new products is not their thing, they will recycle older products as market it as new. There is one gun that fits the memo here. The Gryazeb Shipunov (GSh) 630 auto cannon. License manufactured by the OFB for the Navy for a long time now, the OFB knows the gun inside out, the gun has a range of 4 km similar to the OFB's "new" gun. To be fair the Gsh 30-1 would also fit the bill, but its not going to have the same rate of fire as the auto cannon.

View attachment 12201

The Gsh 630 guns are the two in the middle. One with a sleeve, one with out.

The Russians have also used the gun to make a wide variety of products, For example :

View attachment 12202

I knew it.

Didn't expect it to be this ugly though :

Portuguese and Indian companies to work on UAVs, aircraft and speedboats

By: Huma Siddiqui | Published: February 14, 2020 7:54:43 PM

In 2017, Prime Minister Modi had visited Portugal when more than 10 agreements were signed in several areas which included space, avoidance of double taxation, nano-technology, biotechnology and higher education.

The two countries signed seven MoUs in various sectors including defence studies and strategic areas, science and technology, aeronautics, and yoga.

India and Portugal on Friday at the end of bilateral talks between Prime Minister Narendra Modi and Portuguese President Marcelo Rebelo de Sousa inked agreements and MoUs covering a wide range of sectors including defence. Seven agreements signed include the cooperation in setting up a national maritime museum heritage complex in Lothal, Gujarat, maritime transport and port development, mobility partnership and investments and start-ups.

Also the two countries signed seven MoUs in various sectors including defence studies and strategic areas, science and technology, aeronautics, and yoga. Portuguese group CEiiA (Centre of Excellence for Automotive Industry Innovation) and Hindustan Aeronautics Limited (HAL) has signed an MoU for establishing a partnership for the development of new projects which are related to the aeronautical and space technology.

Portugal is the largest international partner of the multi-mission airlifter Embraer KC-390 Programme. Embraer Company of Brazil will deliver five of these aircraft to Portugal from 2023. Portugal has been actively involved in the KC-390 programme from the development to the production of the aircraft.

According to a top official, “Portugal is interested in using this expertise with state-owned HAL.” UAVISION of Portugal and the Indian company VEDA Defense Systems have signed an agreement which focuses on technology transfer, production and co-production of unmanned aerial systems. A training centre for the drones is expected to be created in India, with Portuguese know-how.

Keeping business opportunities in Africa in mind on Saturday Shipyards of Peniche and the GOA Shipyard is expected to sign an MoU for the construction of speedboats in Portugal and India. This co-production will be done through the transfer of technology (ToT) which incorporates polymers to be utilized in the hulls.

This will be inked in the presence of the visiting President Marcelo Rebelo de Sousa, who reaches Goa tomorrow who is accompanied by a high-level delegation, in his first ever visit to India.

In 2017, Prime Minister Modi had visited Portugal when more than 10 agreements were signed in several areas which included space, avoidance of double taxation, nano-technology, biotechnology and higher education. The pacts signed after Modi-Sousa talks included a joint declaration a bilateral mobility partnership and another on maritime transport.

Portuguese and Indian companies to work on UAVs, aircraft and speedboats

By: Huma Siddiqui | Published: February 14, 2020 7:54:43 PM

In 2017, Prime Minister Modi had visited Portugal when more than 10 agreements were signed in several areas which included space, avoidance of double taxation, nano-technology, biotechnology and higher education.

The two countries signed seven MoUs in various sectors including defence studies and strategic areas, science and technology, aeronautics, and yoga.

India and Portugal on Friday at the end of bilateral talks between Prime Minister Narendra Modi and Portuguese President Marcelo Rebelo de Sousa inked agreements and MoUs covering a wide range of sectors including defence. Seven agreements signed include the cooperation in setting up a national maritime museum heritage complex in Lothal, Gujarat, maritime transport and port development, mobility partnership and investments and start-ups.

Also the two countries signed seven MoUs in various sectors including defence studies and strategic areas, science and technology, aeronautics, and yoga. Portuguese group CEiiA (Centre of Excellence for Automotive Industry Innovation) and Hindustan Aeronautics Limited (HAL) has signed an MoU for establishing a partnership for the development of new projects which are related to the aeronautical and space technology.

Portugal is the largest international partner of the multi-mission airlifter Embraer KC-390 Programme. Embraer Company of Brazil will deliver five of these aircraft to Portugal from 2023. Portugal has been actively involved in the KC-390 programme from the development to the production of the aircraft.

According to a top official, “Portugal is interested in using this expertise with state-owned HAL.” UAVISION of Portugal and the Indian company VEDA Defense Systems have signed an agreement which focuses on technology transfer, production and co-production of unmanned aerial systems. A training centre for the drones is expected to be created in India, with Portuguese know-how.

Keeping business opportunities in Africa in mind on Saturday Shipyards of Peniche and the GOA Shipyard is expected to sign an MoU for the construction of speedboats in Portugal and India. This co-production will be done through the transfer of technology (ToT) which incorporates polymers to be utilized in the hulls.

This will be inked in the presence of the visiting President Marcelo Rebelo de Sousa, who reaches Goa tomorrow who is accompanied by a high-level delegation, in his first ever visit to India.

In 2017, Prime Minister Modi had visited Portugal when more than 10 agreements were signed in several areas which included space, avoidance of double taxation, nano-technology, biotechnology and higher education. The pacts signed after Modi-Sousa talks included a joint declaration a bilateral mobility partnership and another on maritime transport.

Portuguese and Indian companies to work on UAVs, aircraft and speedboats

An Interesting post found on reddit

Do read the questions and replies.

Do read the questions and replies.

Last edited: