Make Indian Subs Great Again

Why India needs to scrap a Rs 1 lakh crore imported submarine buy and built on its Atmanirbhar N-sub line

By Sandeep Unnithan

Updated On: 21 Feb 2025 12:47

M

Eight years ago, Manohar Parrikar told me of a conundrum in the defence ministry. “The strategic submarine (the 6000 ton Arihant class SSBN) is 80 per cent indigenous, but the conventional submarine (the 1800 tonne Scorpene class submarines) is 80 per cent imported.” Parrikar used the analogy to explain legacy issues challenging the government’s Make in India indigenization drive.

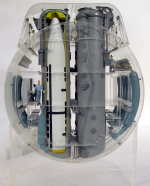

India has built its own nuclear-powered submarines but has not built its own conventional submarines. It is a conundrum because nuclear submarines are among the most complex defence platforms ever built. Powered by a nuclear reactor, they can stay underwater almost indefinitely, their endurance limited only by crew fatigue and food supplies. India is only the sixth country in the world to build its own nuclear submarines. When they carry nuclear-tipped ballistic missiles, they become strategic platforms or SSBNs; armed with conventional missiles and torpedoes, they are called attack submarines or hunter-killers (SSNs). Nuclear submarines are larger, carry heavier weapon loads, move faster and dive deeper, hence they are deadlier than conventional submarines (SSK) which must surface for air to run their diesel engines and recharge their batteries. This is why the US, UK and France have long phased out conventional submarines. France however, continues to design and develop SSKs for the lucrative export market.

The four Arihant class SSBNs are India’s biggest technological breakthroughs. The Arihant and Arighat are in service with the larger S4 and S4* displacing over 7000 tonnes each, slated for induction by 2026. These vessels tested the limits of India’s engineering prowess, were built in the teeth of foreign technology denial regimes, unstinting design support from India’s strategic partner Russia, and steered by the Advanced Technology Vessel (ATV) project. The project operates under the Prime Minister’s Office, directly supervised by National Security Adviser Ajit Doval.

The Indian Navy also operates a fleet of 17 conventional submarines primarily deployed against its proximate naval adversary Pakistan in the shallower Arabian Sea. Six P75 Scorpene class submarines, were bought from France in 2005 for Rs 19,000 crore. The vessels were built at the Mazagon Docks Ltd with French assistance and the sixth unit the INS Vaghsheer delivered to the navy last December. But as Parrikar presciently noted, the Scorpene has a high import content— the vessel’s combat management system (CMS), weapons, missiles and torpedoes, which account for nearly half the cost of the submarine, are imported. The CMS source codes are with the French which means Indian weapons can be integrated into the platform only with French assistance. The French have refused to integrate Indian missiles into their submarines in the past. Even the steel for the submarines was imported from France. Worse, no domestic vendor base was created for the six units, which means continued dependence on imported components through their service life.

In sharp contrast, all four Arihant class submarines have an indigenous component of over 80 per cent. This is because strategic submarines as the secure second leg of a nuclear triad as outlined in India’s draft nuclear doctrine released in 1999, are weapons of deterrence. By assuring a retaliatory second-strike, they ensure a nation’s survival by deterring enemies from launching surprise nuclear first-strikes. Indigenisation is vital to ensuring platform availability.

A crucial part of the Arihant, the 83 MW light water pressure reactor is built indigenously by BARC, a feat for a country yet to produce its own fighter engine, tank engine or warship gas turbine. BARC leveraged the Indian partner ecosystem developed from the 1960s for its nuclear power plants, to generate supplies from the component level upwards, to build these reactors. The K-4, K-5 and K-15 submarine launched ballistic missiles (SLBMs) arming the Arihant class are developed by the DRDO, the ‘Panchendriya’ combat and the Ushus indigeneous sonar by Bharat Electronics. The submarine was built to a Russian design, but the pressure hull was fabricated by L&T in Hazira, Gujarat, and ferried to the Arihant’s final assembly line, the Shipbuilding centre in Visakhapatnam, Andhra Pradesh. Since its inception in 1984 under its first Director General, the visionary Vice Admiral MK Roy, the ATV project reached out to Indian industry, painstakingly created a vendor base of over 125 companies across the country to source the pumps, pipes, pressure valves, hydraulic systems, electronics, and all other essential equipment for the massive project. They ensured design and IP for the firms resided within India, meaning these submarines can be serviced and upgraded in-country through their 30-year service lives. “Our nuclear submarine project was Atmanirbhar (self sufficient) from inception,” says Vice Admiral PC Bhasin, former DG ATVP.

But here’s the tragedy. The Arihant line ended with the fourth unit, the S4* ordered in 2014. The skillsets and industrial base created for the Arihant class have idled since the last hull was fabricated at Hazira in 2017. Construction of the next batch of SSBNs, the 12,500-ton S5 SSBNs, has begun and the first unit is due in the early 2030s.

The inability to leverage domestic capabilities for the conventional programme is what has led to the SSK import dependence. There are less than a dozen countries which can design and build their own SSKs. India is not among them. Transfer of technology (ToT) clauses in the 1981 deal for four HDW submarines costing Rs 465 crores were not implemented because the company was blacklisted after bribery allegations in 1987. In the case of the French deal in 2005, the ToT was simply not pursued. Ironically, a South Korean firm recently offered to sell India a version of the same submarine it had purchased from HDW in 1987. South Korea reverse-engineered the design to build its own series of larger, more capable SSKs which it now offers for export. This is something India has been unable to do. The Directorate General of Naval Design has designed everything from frigates to aircraft carriers but its Submarine Design Group (SDG) has designed the under-production S5 submarines but not SSKs.

“The DGND (SDG) may be the only design establishment in the world which has had the luxury of observing diverse submarine design philosophies of East and West– HDW, the Scorpene, the 877EKMs, Arihant and Chakra. They should be ready to make rational design choices without P75(I),” says Vice Admiral KN Sushil, former CinC, Southern Naval Command.

Recent developments portend gloom for submarine design capability. On February 12, a joint statement issued in Paris by Prime Minister Modi and President Macron mentioned the P75- Advanced Scorpene (AS) project. India plans to buy these three additional submarines from France reportedly for Rs 33,000 crore. No details were released but these vessels are believed to be a 2000-ton Scorpene with features borrowed from the French Shortfin Barracuda class SSK. Each P75-AS submarine is believed to cost upwards of Rs 10,000 crores. That’s the cost of the last Arihant class submarine the S4* ordered in 2014. Rather than hold France accountable for not transferring technology, it would seem India has chosen to reward them by greenlighting the 2005 contract’s ‘option clause’ for three more submarines. The joint statement mentions the addition of an Indian CMS and the DRDO’s indigeneous Air Independent Propulsion (AIP) plug which increase an SSK’s underwater stay. These additions will increase the Scorpene’s indigenous component, but the platform will essentially remain a foreign design, with France in the driver’s seat with no knowledge gained by Indian designers to build our own SSKs. They will be handed a design solution rather than solving a problem—the crucial difference between know-how and know-why.

South Korea and China were successful in their programs, Admiral Sushil says, because they persisted with the adopted build philosophy allowing their industry to consolidate and establish base-line technology thresholds that then form the basis for improvements.

India has built two separate classes of foreign SSKs, hopes the elusive ToT to will come from yet another foreign deal—six Project 75(India) submarines, estimated at Rs 70,000 crore which it hopes to buy from France’s neighbors— Germany or Spain. One of two shortlisted companies will transfer conventional submarine building knowhow to an Indian yard, making it the third contract to buy foreign conventional submarines in four decades. The conundrum is set to continue.

India’s submarine crisis

India has a vast coastline of over 11,000 km, and its position as the world’s fastest growing economy is entirely dependent on secure SLOCs. Over 85 per cent of India’s energy is imported over the seas, over 95 per cent of the trade by volume and 70 per cent by value moves over the seas. India’s maritime strategy to deter adversaries in the vast Indian Ocean region revolve around two carrier battle groups to protect India’s sea lanes of communication (SLOCs). Submarines, both conventional and nuclear, are a key component of this strategy.

Indian admirals point to China’s plans to field at six aircraft carriers as the reason India must build them too. But they miss China’s mammoth nuclear submarine building project meant to address an undersea imbalance with the US – China has only six SSNs, the US has fifty. China’s nuclear submarine building programme will start delivering between four and six nuclear submarines a year says Rear Admiral Monty Khanna, former flag officer Foreign Cooperation and Naval Intelligence. China could have as many SSNs as the US Navy within a decade and flood the Indo-Pacific with one of the deadliest offensive naval platforms ever made. Admiral Khanna believes China could eventually lease an SSN to the Pakistan Navy, as Russia has done for India, or even base SSNs in Pakistan to shorten transit time into the Indian Ocean.

This year, China will deliver the first of eight Type 039A Yuan class SSKs to the Pakistan Navy, increasing its existing fleet of three SSKs to 11.

The Chi-Pak nexus could potentially impinge India’s maritime security and threaten its SLOCs. This nexus overlaps the crisis in India’s conventional submarine arm. Ten of the Indian Navy’s existing fleet of 17 SSKs are of 1980s vintage and near retirement. The Indian Navy’s National Competence in Submarine Building, (aka the 30-year submarine building plan) was drawn up in the late 1990s. It has delivered only 6 of a planned fleet of 24 SSKs. The allure of European firms dangling ToT carrots, ensure the painstaking process of designing an indigenous SSK remains forever down the road.

The egregious capability gap extends to SSNs as well. The Indian navy is the only major global force without an SSN. That gap will be partially filled only by around 2028 when one Akula class SSN, the Chakra-3, arrives on a ten-year lease from the Russian Federation. The six nuclear powered attack submarines envisaged under the national strategic capability project in the early 2000s and revived by Parrikar a decade ago, got budgetary sanction only last year. The first two SSNs will be built indigenously for Rs 45,000 crore. Because they are being designed from scratch with a new 190 MW reactor, it is realistic to assume that the first unit will be delivered 15 years from now- by 2040. In the interim, the navy’s requirement for SSNs will grow—they will be needed to accompany carrier battle groups, launch long range strikes against shore targets, sink enemy warships and merchantmen or protect SSBNs when they are most vulnerable– entering and leaving their secure bases. The navy also needs new SSKs to replace ageing boats which will start going out of service in the next decade. There are no submarines either to offer friendly navies. In 2022, the navy gifted one of its in-service Russian-built Kilo class submarines, the INS Sindhuvir to the Myanmar Navy.

China’s explosive submarine construction is contrasted by the deathly silence in India’s submarine production lines in Mumbai, Hazira and Visakhapatnam.

There is a crisis of numbers. And this crisis is largely a self-made one. Delays, indecision, inter-departmental rivalries, staccato programmes, undersea blindness, and the failure to leverage in-house skills has resulted in what can only be called a self-created anti-submarine warfare programme– one that has killed indigenous submarine capability at the drawing board.

The DRDO’s 2016 proposal for the ATV Project team to design an indigenous Project 76 SSK was stalled by the navy for five years before being greenlit in 2021. Another proposal from within the navy for SSNs based on the Arihant class did not find favour with naval brass who felt the 83 MW reactor was underpowered. Nothing less than a 190 MW reactor would do since the SSN had to achieve speeds of over 30 knots.

L&T, meanwhile, leveraged its ATV project experience to design India’s first conventional submarine — the 400-ton SOV-400 (Special Operations Vessels). The vessel is a mini conventional submarine with an indigenous CMS, sonar and torpedoes and can launch marine commandos in swimmer delivery vessels. It is the building block for a larger indigenous conventional submarine, but the firm is yet to get an order from the navy.

The Arihant class SSN

Prime Minister Vajpayee and his NSA Brajesh Mishra and key project officials breathed life into the stalled ATV project after the 1998 Pokharan-2 nuclear tests. Twenty-seven years later, it is for the duo of Prime Minister Modi and his NSA Ajit Doval to take another call. Will India’s indigenisation interests be served by nine imported submarines costing over 1 lakh crore in foreign exchange?

Or will the money spent importing three French P75-AS Scorpenes and six Project-75(I) units be better spent towards kickstarting indigeneous submarine projects. For the cost of three Scorpene-AS, India could build four indigenous Arihant class nuclear submarines, reconfigured as attack submarines. The navy would have funds left over to design the P76 indigeneous submarine leveraging all of India’s submarine building expertise for a new line of ‘Born in Bharat’ SSKs. The project team could source the detailed design documents of the Scorpene submarines currently held by the Indian Navy’s SDG (obtained from Armaris, the Franco-Spanish company which signed the 2005 Scorpene submarine contract).

Steered by the ATV Project team, a public-private project could restart the two dormant conventional submarine production lines at L&T and Mazagon Docks Ltd to cut down delivery time. These SSK design, produced at lesser cost than European submarines, could also be exported to friendly Asian countries like Indonesia, Malaysia, Philippines, Vietnam and Taiwan.

The ATV Project could also restart the Arihant production line. Since the Arihant is a mature design, steel for the first unit could be cut almost immediately with the first unit delivered in less than a decade. This project will keep the art of submarine building intact and enable a smooth transition towards building S5 and P77 boats.

This would not be the first time India has exited a foreign contract midstream. In 2018, India walked away from a Russian partnership for joint-development of a fifth-generation fighter, to focus on the indigenous AMCA.

Nor will this be the first time any country has reassessed its submarine priorities. In 2021, Australia opted out of a project to buy 12 French Shortfin Barracuda submarines for $ 89 billion dollars to acquire instead the AUKUS nuclear powered submarines from the US and UK.

India’s own AUKUS, the Arihant class SSNs, will be nearly identical to the first two SSBNs in service, but without their nuclear weapons. Their SLBM tubes can be reconfigured to fire at least 16 long-range missiles of various types depending on the mission profile— Brahmos anti-ship missiles, Nirbhay land attack cruise missiles or the DRDO’s hypersonic long range anti-ship missiles. The submarine can sprint to a top speed of 24 knots. This might be slower than contemporary SSNs, but this handicap can be compensated by the submarine’s long-ranged weapons which can strike targets at extended ranges of over 500 km (five times the range of the Scorpene’s French-made Exocet missiles) with heavier warheads. Dedicated VLS tubes for launching missiles mean each submarine can carry a full load of 30 torpedoes. (Conventional submarines can fire missiles only through their torpedo tubes, hence carry fewer weapons).

This would make it one of the Indian Navy’s deadliest force multipliers that can easily outmatch SSKs in striking power.

The force multiplier effect will extend into Indian industry as well, kickstarting the industrial ecosystem created by the Arihant project and reviving manufacturing, with all submarines serviced and upgraded by an indigenous vendor base. Indigeneous submarines are the only way out to urgently boost India’s offensive naval power and boost Atmanirbhar Bharat.

Make Indian Subs Great Again

M

M