Any idea why IA tank crew wear black instead of regular camo ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tank crews needed to work with oil and even today do so. It does not show in the black dungarees. I guess, that would be the reason.Any idea why IA tank crew wear black instead of regular camo ?

Also, in commonwealth armies the Black Beret is a tank man.

Quick question..is there any technical or operational reason why the gun mantlet (area around the gun barrel attached to the hull) is not covered by wedge-shaped composite/ERA armour on the Mk1A?

Isn't that a vulnerability in battle since the frontal arc is going to take a lot of punishment?

Also, would it be possible to add a second CPS (commander's panoramic sight) for the gunner and armour plate the spot occupied by the current sight? TIA.

Isn't that a vulnerability in battle since the frontal arc is going to take a lot of punishment?

Also, would it be possible to add a second CPS (commander's panoramic sight) for the gunner and armour plate the spot occupied by the current sight? TIA.

You talking about something like this broQuick question..is there any technical or operational reason why the gun mantlet (area around the gun barrel attached to the hull) is not covered by wedge-shaped composite/ERA armour on the Mk1A?

Isn't that a vulnerability in battle since the frontal arc is going to take a lot of punishment?

Also, would it be possible to add a second CPS (commander's panoramic sight) for the gunner and armour plate the spot occupied by the current sight? TIA.

View attachment 36077

:

:

Image Source: Reddit

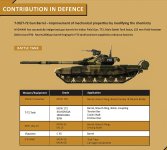

Recently, There were news that India has developed an excellent Sandwich type material using aluminum and other material which showed excellent resistance against direct heat of TNT without much of damage in test. It is said that same will go into future tank.

Sort of. I meant moving the gunners sight to the top of the turret and plugging the armour gap on the front of the turret, including around the spot where the gun barrel attaches to the turret. Needs full protection on the frontal 90 deg arc, imo.

Like the Russians have done on the latest T-90M variant. Not that it matters but the aesthetics are awesome. The best looking Russian tank, EVER.

Recently, There were news that India has developed an excellent Sandwich type material using aluminum and other material which showed excellent resistance against direct heat of TNT without much of damage in test. It is said that same will go into future tank.

I remember reading that ARDE/HEMRL(?) were developing lighter high nitrogen steel for the MK2 to bring down the weight + NERA (Non-explosive reactive armor) tech. But it seems they went with ERA blocks on the MK1A.

Don't know if the army changed specifiications but NERA would have been more durable.

I can't imagine them changing exploded ERA blocks on field.

Quick question..is there any technical or operational reason why the gun mantlet (area around the gun barrel attached to the hull) is not covered by wedge-shaped composite/ERA armour on the Mk1A?

Isn't that a vulnerability in battle since the frontal arc is going to take a lot of punishment?

Also, would it be possible to add a second CPS (commander's panoramic sight) for the gunner and armour plate the spot occupied by the current sight? TIA.

View attachment 36077

Both the mantlet and gunner sight are major weaknesses.

RM Rajnath Singh visited Field Gun Factory under AWEIL. It specializes in manufacturing barrel & breach assemblies of various artillery guns & tank

Hammer forged billet lays on the ground. This billet will be machined into a barrel as seen in the lathe:

The new assembly shop:

The new heat treatment facility:

Finished 120mm barrel of the Arjun. You can see the rifling grooves inside the bore:

Hammer forged billet lays on the ground. This billet will be machined into a barrel as seen in the lathe:

The new assembly shop:

The new heat treatment facility:

Finished 120mm barrel of the Arjun. You can see the rifling grooves inside the bore:

Found 2 more photos:

RM near semi-finished Arjun 120mm barrels:

View attachment 37694

View attachment 37695

View attachment 37702

View attachment 37701

The gas extraction ports on the barrels are clearly visible here.

Arjun main gun's breech:

View attachment 37700

Finished barrel & breach assembly:

View attachment 37696

View attachment 37697

View attachment 37698

View attachment 37699

View attachment 37703

If I recall correctly, our issue was manufacturing the smoothbores not making the alloys. Although the last time I've heard of this issue was a decade ago. They may have worked it out by now.MIDHANI is said to supply 125mm barrels with "modified chemistry" but I dunno much about it.

It wouldn't make sense for MIDHANI to make domestic alloys for the barrel & breech without having domestic manufacturing tech. Without domestic manufacturing capacity, we would have to send these alloys over to Russia to have them forged.

Yea, reading old audits it seems that they were initially limited to supplying just the rolled bars to the then-AWEIL bodies for forging, tempering and machining into finished barrels for the T-72s but there were some tempering defects. Then there's this new "modified chemistry" material which comes around 2000 against which CQA(AVA) clearance was only accorded in 2010 (not to be confused with Project MAPLE) and then some more years into delays because of material shortage (overburdened orders).If I recall correctly, our issue was manufacturing the smoothbores not making the alloys. Although the last time I've heard of this issue was a decade ago. They may have worked it out by now.

It wouldn't make sense for MIDHANI to make domestic alloys for the barrel & breech without having domestic manufacturing tech. Without domestic manufacturing capacity, we would have to send these alloys over to Russia to have them forged.