This Engineer Is Helping to Make India a Global Semiconductor Hub

He is leading the development of next-generation chips

KATHY PRETZ

24 SEP 2023

Tushar Sharma

Tushar Sharma

joined Renesas Electronics executive vice president Sailesh Chittipeddi [far left] and the company’s CEO Hidetoshi Shibata in presenting India’s Prime Minister Narendra Modi with a framed 5G chipset. Photo: PRIME MINISTER OF INDIA OFFICE

When Tushar Sharma was a young boy growing up in Jamnapaar, India, a densely populated area outside of Delhi, he never imagined that someday he would meet the country’s prime minister.

That memorable event occurred in May, when Sharma and a delegation from his employer, Renesas Electronics, met with Narendra Modi to discuss how the semiconductor company could support the prime minister’s India Semiconductor Mission and Digital India initiative. The initiative aims to improve the country’s reliance on hardware infrastructure and to become a global hub for electronics manufacturing and design.

Sharma, a semiconductor engineer, was instrumental in organizing the meeting for the Tokyo-based company. He heads the recently opened Renesas-Tata Consultancy Services Joint Innovation Center, in Bengaluru. The center focuses on radio-frequency, digital, and mixed-signal design, as well as software for next-generation chips focusing on 5G, artificial intelligence, the Internet of Things, and more.

Renesas’s efforts for the “Made in India” ecosystem reflects the company’s expertise in manufacturing, telecommunications, automotive, and advanced semiconductor design, Sharma says.

“The idea is to enable more end-to-end solutions for India as well as other global markets,” he says. “India has to become a self-sustaining R&D hub.”

Building a thriving semiconductor industry

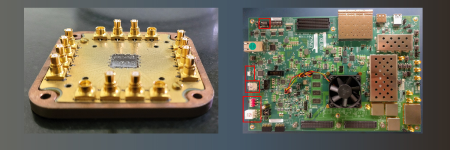

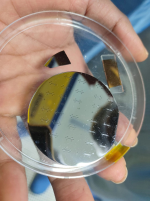

At the meeting with Modi, Sharma presented the prime minister with a cutting-edge 5G millimeter-wave and sub-6-gigahertz chipset designed by Renesas’s R&D teams in Bengaluru and San Diego.

“The prime minister displayed a genuine fascination with the chipset and talked about the technical intricacies of the integrated chip,” the IEEE member says. “He asked about the silicon node and the fabrication facility that created it."

“I firmly believe the development of these critical chips is vital for the greater public good,” Sharma says. “Those working in industry can be change agents and have a meaningful impact on society, such as advancing technology for humanity. After all, that is the motto of IEEE.”

Sharma worked for several years as an RF engineer in the semiconductor industry before joining Renesas in 2021. He is based at the company’s San Diego office but travels frequently to Bengaluru. Sharma’s research includes developing gallium nitride technology, advanced integrated circuits for 5G and beyond, and millimeter-wave transmitters.

In addition to leading the innovation center, he is a visiting professor at the Indian Institute of Technology Bombay and advisor to the university’s Center for Semiconductor Technologies. The SemiX focuses on workforce development and entrepreneurship by serving as a common interdisciplinary platform between academia, industry, investors, and government. The center supports the Indian Semiconductor Mission, which aims to grow the nation’s chip industry.

When Sharma asked the prime minister to share his vision for India’s future, Modi told him it was important that young professionals and those working in the scientific community be involved in fostering inclusive growth, developing talent, and improving the skills of those living in the country’s rural areas, focusing on technology development with integrity, inclusion, and innovation.

Sharma says he finds Modi’s own career inspirational, because he experienced the challenges of growing up in a financially strained environment.

“His tech-savvy approach—and active presence on social media with more than 200 million followers—allows him to connect and engage with the youth, addressing their concerns and aspirations in a relatable manner,” he says. “What resonates with young professionals is the belief that no dream is too big, and no obstacle is too insurmountable when fueled by a strong sense of purpose and a vision for a brighter future.”

From astrophysicist to semiconductor engineer

Growing up in a financially strained environment, Sharma joined the Society of Amateur Radio Astronomers, seeking mentorship and support from nearby science clubs. He learned how to set up antennas and radios to track celestial events.

He wanted to monitor and record the radio waves from the annular solar eclipse in 2013, but he couldn’t afford a radio, so he decided to build his own. He bartered with shop owners to get free parts in exchange for tutoring their children.

While building his radio, he says, he fell in love with engineering.

“I went through so much emotion and hard work that I got attracted to the engineering field,” he says. “I realized that engineering is the backbone of many things that are used in our daily lives.”

To get to the best place for him to view the eclipse—Varkala, Kerala, which is 2,500 kilometers from his hometown—he took buses and trains, and he walked at times. At the viewing site, he met solar physicist Subramaniam Ananthakrishnan. After Sharma showed him the radio he had built, Ananthakrishnan encouraged him to pursue a career as a semiconductor engineer and challenged him to design an amplifier that did not oscillate and an oscillator that didn’t amplify. Sharma did just that.

“Those working in industry can be change agents and have a meaningful impact on society.”

He earned a bachelor’s degree in engineering in 2009 from Guru Gobind Singh Indraprastha University, in Delhi. He wanted to continue his studies in the United States, he says, but the tuition was too expensive.

By chance, he attended a session on microwaves given by IEEE Fellow Fadhel Ghannouchi, who taught electrical and computer engineering at the University of Calgary, in Alberta, Canada. Sharma told Ghannouchi about his research and his work with radio waves. Ghannouchi encouraged him to apply for a Killam Doctoral Scholarship to the Canadian university, and he was accepted. Sharma earned a Ph.D. in electrical and computer engineering in 2018 from the university, followed by a postdoc stint at Princeton. Calgary recognized him with a Schulich Early Achievement Alumni Award in 2019.

An active student humanitarian

Since his college days, Sharma has been using his technical skills to give back to communities around the world. He started as an IEEE student branch chair. His focus, he says, has been to encourage students to pursue a STEM education and to bridge the digital/education divide.

When he moved to Canada, he joined the IEEE Southern Alberta Section and served as chair of its Young Professionals affinity group. He helped reinvigorate the group, which received the 2015 Young Professionals Hall of Fame Award. The honor recognizes groups that have formed collaborations with local industry, organized quality events, engaged with other IEEE units, and held activities that grew their membership.

Sharma helped found the section’s IEEE Special Interest Group on Humanitarian Technology. The SIGHT group partners with local organizations to bring technology to underserved communities. Looking for people who needed help, he learned about the indigenous community in Canada.

“I was shocked to see that within first-world countries, there is still so much disparity,” he says.

The IEEE SIGHT group built the infrastructure to bring free Wi-Fi to the Maskwacis reserve, in central Alberta. The project received US $20,000 from what is now the IEEE Humanitarian Technologies Board.

“I understood one thing: that it’s not always about the solutions; it’s about working on the right problems,” Sharma says of his SIGHT work.

“Wireless connectivity is a basic need for individuals because that’s what connects them to the outside world and the global ecosystem,” he says. Thanks to the project, he says, residents could start small businesses and sell their products online.

“Technology is not just about high-end IC design,” he says. “It is also about how you can translate that technology into public good.”

In 2021 Sharma was the youngest member to be elected to the IEEE Microwave Theory and Technology Society board, on which he still serves. He says he values getting to meet the other board members, who include some of the best researchers in their field who are shaping the future of technology

What’s more, he says, “I get to evolve my personality, understand how technology trends are changing, and what the strategies are.

“For my professional career, membership has helped me expand my network and sharpen my technical know-how. Be it your personal or professional life, learning and service is an inevitable process. The more you serve, the more you learn and grow.”

This Engineer Is Helping to Make India a Global Semiconductor Hub