IISc-Bengaluru develops indigenous fuel injector for fighter planes, to be tested on AMCA

Chethan Kumar / TNN / Updated: Nov 19, 2024, 13:34 IST

Researchers at the Indian Institute of Science (IISc) have developed a new high performance fuel injector system for fighter aircraft. The injector, designed using 3D printing, produces exceptionally small fuel droplets for efficient combustion. Tested successfully under various conditions, the injector surpasses existing technologies and is slated for use in India's AMCA.

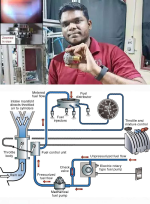

IISc's SK Thirumalaikumaran with the new indigenous fuel injector for fighter jets developed at the institute.

IISc's SK Thirumalaikumaran with the new indigenous fuel injector for fighter jets developed at the institute.

BENGALURU: Researchers at the Indian Institute of Science (IISc) achieved a significant breakthrough in aerospace technology by developing a next-generation high-performance fuel injector system for fighter aircraft. It is slated for implementation in Advanced Medium Combat Aircraft (Amca), India’s fifth-generation single-seater fighter jet.

“We’ve developed a new high-performance, high-shear swirl injector. It produces exceptionally small droplets, crucial for efficient fuel-air mixing and complete combustion,” Prof Saptarshi Basu, the lead investigator of the project, told TOI.

The innovative technology, developed as part of a Defence Research and Development Organisation (DRDO) Centre of Excellence for Propulsion Technology (CoPT) programme, represents a complete indigenous solution from design to testing. Basu’s team, which includes SK Thirumalaikumaran and Sonu Kumar, worked with DRDO’s Gas Turbine Research Establishment (GTRE).

“The high-shear fuel injector, developed through advanced 3D printing techniques, demonstrated superior performance compared to existing commercial alternatives across all key parameters, including droplet sizing, spray pattern formation, flame stability, and flow field consistency,” Basu said.

The comprehensive development process involved multiple stages of testing and validation using world-class experimental facilities at IISc. “This achievement represents a perfect marriage between fundamental fluid mechanics research and practical applications in aerospace technology. Our team utilised a sophisticated experimental facility capable of handling air supply up to 40 bar and maximum flow rates of 6 kg/second, enabling thorough testing of the injector’s capabilities,” Basu said.

Basu, while pointing out that a final schedule for when it will be tested on AMCA — which is still under development — said that the injector also has the potential to be used in civil aircraft with minimal modifications.

“The development process encompassed multiple technological achievements, including the creation of a high-pressure optically accessible test facility operating at up to 15 bar and advanced flow visualization using simultaneous high-speed PIV [or Particle Image Velocimetry, an optical method of flow visualization] diagnostics,” Basu said.

The team conducted comprehensive testing under various pressure conditions with both gas and liquid fuels, consistently demonstrating the injector’s superior performance over existing solutions.

The project, Basu said, not only yielded multiple scientific papers and patents but also served as a valuable training ground for several students in advanced aerospace technology. “The successful development received high praise during the CoPT review, marking it as a significant milestone in India’s journey toward self-reliance in critical defence technologies. Technical results revealed optimal measurements at different air-to-liquid ratios, confirming the injector's exceptional performance,” Basu said.

IISc-Bengaluru develops indigenous fuel injector for fighter planes, to be tested on Amca | Bengaluru News - Times of India