It's a bit fuzzy. There are no direct answers. I read somewhere that the equiaxed blades with no TBC would have a lifespan of ~500 hrs. DMS4 SC blades can supposedly do 1000+ hrs. I don't know if this 1000+ number is with or without TBC. If we are going for a Niobium/Columbium alloy nozzle then those will need an overhaul at around 1000 hrs too.

Redux of the PARAM supercomputer story. Could you share that article.

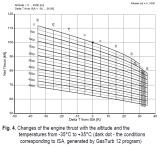

I didn't think our R&D efforts into CMCs had gone far enough for us to make engine core components out of it. Here is a comparative chart I made of the performance achieved by Kaveri K9 vs. performance expected from AMCA's engine:

View attachment 39306

If we have gone close to 1900-2000 K, then AMCA's engine is very much within reach. 1900-2000 K is 5th gen engine territory. If this is true, then engine collab with foreign OEM might not be needed at all.