We Have blisk tech and so do Russians.The 51/81 KN version of Kaveri is no more.

The goal now is 45/74 KN.

So Kaveri is not even being developed for the current production of Mk1As. And GTRE's main mandate for now is IUSAV and FUFA, hence the lower thrust.

Coming to your other posts:

A 90 KN version of Kaveri is a future option and a 110 KN new engine is backup for AMCA in case negotiations fail. But neither can be pursued independently without F414-related production technologies. We still don't have blisk, bling or laser drilling tech for example. All of these have to come from the US over the next 5 years. Or we have to take another 10 years to develop everything from scratch before starting one.

So even if we have developed CMC, we can't machine and coat it without F414 tech. That's where we are right now.

We Have blisk tech and so do Russians.

What we have is still experimental. We have experimental techniques for almost all of those processes that will come via F414, but it will still take us 10 years to get all the tech we want on our own that can result in a fully functional engine that the IAF will be happy with. For now, HAL is aiming to build up tech that can be used in less capable aircraft like large UAVs that uses nickel alloys.

The Russians aren't interested in providing us ToT. They have caught up with the West with AL-41F1 and AL-51F, but its new tech for them too, so I don't think they are going to hand it over in the timeframe we want them to. The Americans and French are willing to provide tech that's going into AL-51F, but the Russians don't even want to provide us with documentation for their engine.

But Russians did offer complete fabrication of these engines from raw material stage in India. But they do not want to share full IPR.What we have is still experimental. We have experimental techniques for almost all of those processes that will come via F414, but it will still take us 10 years to get all the tech we want on our own that can result in a fully functional engine that the IAF will be happy with. For now, HAL is aiming to build up tech that can be used in less capable aircraft like large UAVs that uses nickel alloys.

The Russians aren't interested in providing us ToT. They have caught up with the West with AL-41F1 and AL-51F, but its new tech for them too, so I don't think they are going to hand it over in the timeframe we want them to. The Americans and French are willing to provide tech that's going into AL-51F, but the Russians don't even want to provide us with documentation for their engine.

But Russians did offer complete fabrication of these engines from raw material stage in India. But they do not want to share full IPR.

We are not looking for IPR, but they are preventing us from replacing their alloys with ours which can improve thrust and SFC. Unlike the F414 deal with 100% production tech, we don't have the same for AL-31FP. We produce something like 87% of the engine's total components. They are using IPR protection as an excuse instead.

Our localized tech has significantly improved the AL-31FP but I doubt we can use it without massive investment, basically pay even more for ToT, like what did for the T-90. But the engine is a major source of revenue for them. The Russians say replacing the alloys with Indian ones will void the warranty. Them being so hard-headed is probably why we are not interested in the AL-41F1S.

As for AL-51F, they are willing to sign the same deal as AL-31FP, but after FGFA has finished development and a production agreement is signed for a sizable number. So all that will take 15-20 years to arrive. Even a basic license production deal for an MKIzed Su-57 will take many years before we get to phase 4 production. So this engine will not help develop HAL's production capabilities.

I had once proposed buying 2-3 squadrons of Su-57 on the condition that we can do whatever we want with the MKI's engine, but even if the Russians agree, this still requires us buying the Su-57 anyway. But it's better to risk things with 40-60 jets than with 270.

So the Russians aren't an option to achieve our engine dreams quickly. F414 is the only way. Deliveries will begin in 3 years we will have all the necessary production tech by 2030-31. The goal is to build 100% of the engine using 100% of Indian raw materials eventually.

I really think we need to tell people more clearly. What's limiting us is the "Making" process not design, not building blocks of technology like Single Crystal. But making them reliably, those machinery, having quality control etc aka the process. I bet my left ball, russkies are using Western or most likely German Machinery to make them. If that is the case, then better deal with Uncle Sam. For all its armtwisting, if we could get those process here, our capabilities would increase tremendously.We are not looking for IPR, but they are preventing us from replacing their alloys with ours which can improve thrust and SFC. Unlike the F414 deal with 100% production tech, we don't have the same for AL-31FP. We produce something like 87% of the engine's total components. They are using IPR protection as an excuse instead.

Our localized tech has significantly improved the AL-31FP but I doubt we can use it without massive investment, basically pay even more for ToT, like what did for the T-90. But the engine is a major source of revenue for them. The Russians say replacing the alloys with Indian ones will void the warranty. Them being so hard-headed is probably why we are not interested in the AL-41F1S.

As for AL-51F, they are willing to sign the same deal as AL-31FP, but after FGFA has finished development and a production agreement is signed for a sizable number. So all that will take 15-20 years to arrive. Even a basic license production deal for an MKIzed Su-57 will take many years before we get to phase 4 production. So this engine will not help develop HAL's production capabilities.

I had once proposed buying 2-3 squadrons of Su-57 on the condition that we can do whatever we want with the MKI's engine, but even if the Russians agree, this still requires us buying the Su-57 anyway. But it's better to risk things with 40-60 jets than with 270.

So the Russians aren't an option to achieve our engine dreams quickly. F414 is the only way. Deliveries will begin in 3 years we will have all the necessary production tech by 2030-31. The goal is to build 100% of the engine using 100% of Indian raw materials eventually.

Last edited:

AL-31FP engine is being produced 100% in India. Russians have not stopped us from modifying any part of it and have not insisted on selling the parts from their production lines. All they said was that if we change those IPR protected parts with our home grown tech, their guarantee will no more be valid. And we have gone head done precisely that and have increased the life of the engine by 500hrs to 2500hrs from russian 2000 hrs.We are not looking for IPR, but they are preventing us from replacing their alloys with ours which can improve thrust and SFC. Unlike the F414 deal with 100% production tech, we don't have the same for AL-31FP. We produce something like 87% of the engine's total components. They are using IPR protection as an excuse instead.

Our localized tech has significantly improved the AL-31FP but I doubt we can use it without massive investment, basically pay even more for ToT, like what did for the T-90. But the engine is a major source of revenue for them. The Russians say replacing the alloys with Indian ones will void the warranty. Them being so hard-headed is probably why we are not interested in the AL-41F1S.

As for AL-51F, they are willing to sign the same deal as AL-31FP, but after FGFA has finished development and a production agreement is signed for a sizable number. So all that will take 15-20 years to arrive. Even a basic license production deal for an MKIzed Su-57 will take many years before we get to phase 4 production. So this engine will not help develop HAL's production capabilities.

I had once proposed buying 2-3 squadrons of Su-57 on the condition that we can do whatever we want with the MKI's engine, but even if the Russians agree, this still requires us buying the Su-57 anyway. But it's better to risk things with 40-60 jets than with 270.

So the Russians aren't an option to achieve our engine dreams quickly. F414 is the only way. Deliveries will begin in 3 years we will have all the necessary production tech by 2030-31. The goal is to build 100% of the engine using 100% of Indian raw materials eventually.

I really think we need to tell people more clearly. What's limiting us is the "Making" process not design, not building blocks of technology like Single Crystal. But making them reliably, those machinery, having quality control etc aka the process. I bet my left ball, russkies are using Western or most likely German Machinery to make them. If that is the case, then better deal with Uncle Sam. For all its armtwisting, if we could get those process here, our capabilities would increase tremendously.

Yeah, German stuff. But it's old stuff now.

AL-31FP engine is being produced 100% in India. Russians have not stopped us from modifying any part of it and have not insisted on selling the parts from their production lines. All they said was that if we change those IPR protected parts with our home grown tech, their guarantee will no more be valid. And we have gone head done precisely that and have increased the life of the engine by 500hrs to 2500hrs from russian 2000 hrs.

There is no report about HAL making 100% of the engine though. The last one reported was 87.7%. So they would have reported if it was 100%.

In the new contract, indigenization percentage by cost has increased from 47 to 54%. And HAL wants to increase it to 63% but was refused. That we agree on.

If it is process then it is a cultural issue, fix that , it requires leadership. Throwing money doesnt solve it , just perpetuates it.limiting us is the "Making" process

You didn't get my message did you? Iam asking about lack of ancillary industries like high precision machinery and operating experience. Not some cultural mumbo jumbo bullshit.If it is process then it is a cultural issue, fix that , it requires leadership. Throwing money doesnt solve it , just perpetuates it.

Just read your sentence all over again , you said lack of quality control not lack of industry.You didn't get my message did you? Iam asking about lack of ancillary industries like high precision machinery and operating experience. Not some cultural mumbo jumbo bullshit.

"What's limiting us is the "Making" process not design, not building blocks of technology like Single Crystal. But making them reliably, those machinery, having quality control etc aka the process"

Vacuum Arc Remelting (VAR) furnace and to produce aerospace-grade Titanium alloy ingots.This is metallurgy. The furnace is means to get para meters require to produce aerospace-grade Titanium alloy. People should have appreciated the achievement.

What're your opinions especially w.r.t the tech deficit suggested in the 2nd tweet ? @Gautam ; @vstol Jockey

I agree to itexcept for the blisk part.

What're your opinions especially w.r.t the tech deficit suggested in the 2nd tweet ? @Gautam ; @vstol Jockey

It appears to me that we have done some significant advance in Hot core tech. I read an article in which we have created a CMC core with a temprature of over 1700*C or 1973K. This seems to have unnerved USA in forcing more controls on us.

Well, well well...

What're your opinions especially w.r.t the tech deficit suggested in the 2nd tweet ? @Gautam ; @vstol Jockey

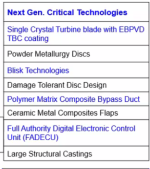

Let's go over these deficiencies point by point. I'll try to be brief:

1. Single crystal blades/vanes with EBPVD: Single crystal blade/vane design & fabrication has been established reliably. This is not an issue anymore. Work is ongoing on improving the composition of alloys used for the SCBs.

The issue is the Electron Beam Physical Vapour Deposition (EBPVD) process. This process is used to deposit ultra-thin layers of Thermal Barrier Coating (TBC) on blades & vanes. DMRL has mastered some other PVD & CVD processes. But EBPVD remains out of reach. The main advantage of EBPVD is that the TBC is coated with extreme uniformity. Other deposition processes don't go anywhere near these levels of uniformity in application. Thus, some spots on the blades/vanes end up receiving a lower than necessary thickness of TBC. Those spots become the initiation point of failure.

We currently get EBPVD machines from Germany. They are very expensive & incredible hard to acquire.

2. Powder metallurgy discs: We do have fabrication capacity of powder metallurgy discs. But our discs so far have had unacceptable levels of porosity to be used on a jet engine. DMRL will probably take 4-5 years to increase the specific gravity of these discs to the point where they can start testing them of engines.

We are currently facing a raw material supply problem for some of our powder metallurgy projects. No investments have been made into setting up domestic raw materials factories.

3. Blisk technologies: We have most of what we need to make Blisks of any size. The only limitation is the lack of large isothermal presses. Those are coming up:

Not related to Kaveri but still has direct implication:

MIDHANI has set up a 2000 MT near-isothermal forge for forging titanium alloys & other super alloys. Tech was developed by DMRL. This forge will produce turbine discs for Adour engines:

View attachment 36814

View attachment 36813

The press:

View attachment 36816

Adour's HPT discs being forged:

View attachment 36817

View attachment 36819

View attachment 36820

View attachment 36818

4. Damage tolerant disc design: We cannot design damage tolerant disks until we have our own engine FOD test facility. This is an infra & investment issue. Not a capability issue.

5. Polymer Matrix Composite Bypass duct: So far, our expertise in fabricating polymer matrix composites is limited to the resin infusion processes. Resin infusion process produces very good quality composites for structural & surface applications. But the problem of using resin infusion process is that some amount of the resin remains stuck within the composite. This remanent slowly dries away naturally within year or so.

Now, bypass ducts aren't part of the "hot" section of the engine. But they do tend to get heated up. That sudden heat shock will cause the all the resin to burn/dry away all at once. That will change the shape of the duct.

We need to master a new process of making composites. A process that does not need resins. Can be done, will take some time though.

6. FADEC: We can make FADEC systems. But even if we design our own chips, they will be reliant on foreign fabricated chips for the sometime. ISRO's SCL after it upgrades to a 28 nm node can take over this role. Or maybe one of the upcoming civilian fabs. Again, this is an infra & investment issue. Not a capability issue.

7 & 8. Large Structural casings & CERMET Flaps: I need to read more about these before I comment.

Thanks for this. Much appreciated!View attachment 39507

Let's go over these deficiencies point by point. I'll try to be brief:

1. Single crystal blades/vanes with EBPVD: Single crystal blade/vane design & fabrication has been established reliably. This is not an issue anymore. Work is ongoing on improving the composition of alloys used for the SCBs.

The issue is the Electron Beam Physical Vapour Deposition (EBPVD) process. This process is used to deposit ultra-thin layers of Thermal Barrier Coating (TBC) on blades & vanes. DMRL has mastered some other PVD & CVD processes. But EBPVD remains out of reach. The main advantage of EBPVD is that the TBC is coated with extreme uniformity. Other deposition processes don't go anywhere near these levels of uniformity in application. Thus, some spots on the blades/vanes end up receiving a lower than necessary thickness of TBC. Those spots become the initiation point of failure.

We currently get EBPVD machines from Germany. They are very expensive & incredible hard to acquire.

2. Powder metallurgy discs: We do have fabrication capacity of powder metallurgy discs. But our discs so far have had unacceptable levels of porosity to be used on a jet engine. DMRL will probably take 4-5 years to increase the specific gravity of these discs to the point where they can start testing them of engines.

We are currently facing a raw material supply problem for some of our powder metallurgy projects. No investments have been made into setting up domestic raw materials factories.

3. Blisk technologies: We have most of what we need to make Blisks of any size. The only limitation is the lack of large isothermal presses. Those are coming up:

4. Damage tolerant disc design: We cannot design damage tolerant disks until we have our own engine FOD test facility. This is an infra & investment issue. Not a capability issue.

5. Polymer Matrix Composite Bypass duct: So far, our expertise in fabricating polymer matrix composites is limited to the resin infusion processes. Resin infusion process produces very good quality composites for structural & surface applications. But the problem of using resin infusion process is that some amount of the resin remains stuck within the composite. This remanent slowly dries away naturally within year or so.

Now, bypass ducts aren't part of the "hot" section of the engine. But they do tend to get heated up. That sudden heat shock will cause the all the resin to burn/dry away all at once. That will change the shape of the duct.

We need to master a new process of making composites. A process that does not need resins. Can be done, will take some time though.

6. FADEC: We can make FADEC systems. But even if we design our own chips, they will be reliant on foreign fabricated chips for the sometime. ISRO's SCL after it upgrades to a 28 nm node can take over this role. Or maybe one of the upcoming civilian fabs. Again, this is an infra & investment issue. Not a capability issue.

7 & 8. Large Structural casings & CERMET Flaps: I need to read more about these before I comment.